Edison Engineering Development Program

Edison Engineering Development Program

The Edison Engineering Development Program (EEDP) has the mission to deliver the world’s most capable Engineers who are adept at solving problems and creating innovative technology for the power industry. EEDP's work to solve one of the biggest climate crisis problems, to provide electricity while at the same time, reducing greenhouse gasses. The Edison program provides accelerated learning and career development by exposing the program members to industry-leading innovators in the power sector.

Members of EEDP will experience world-class training, including functional course work, which sets the foundation for successfully innovating the future of energy. Exposure to a variety of roles in design, testing, performance, controls, and services allow program members to leave EEDP well rounded and ready to tackle the future of energy.

EEDP Opportunities

- Two years of on-program experience comprised of performing meaningful customer-focused work

- Four 6-month rotations resulting in real roles, impact, and responsibility.

-

World-class education opportunities:

- Industry, Product & Leadership Training

- Internal classes taught by GE Vernova Experts

- Train, work and learn with a globally diverse community of young professionals

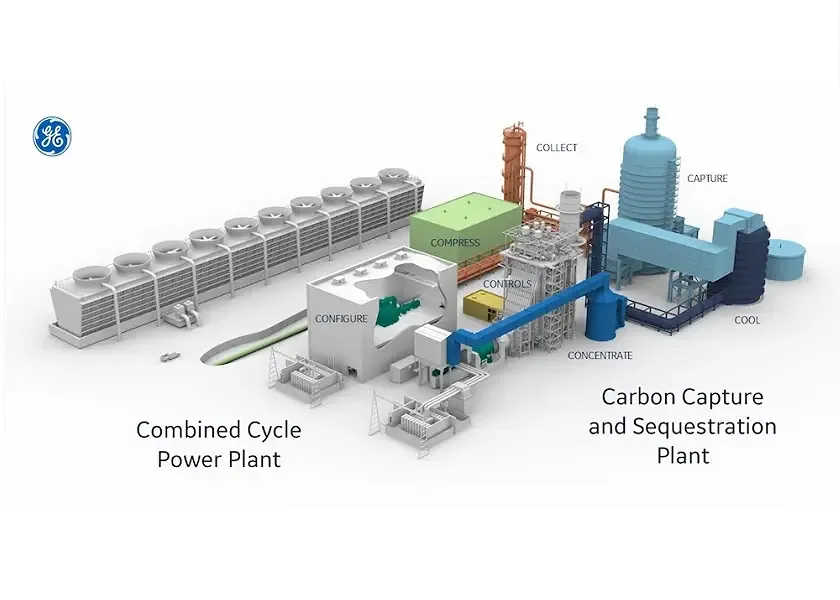

Customer Application Engineering

Customer application engineering is a systems-engineering role that will focus on power plant integration and optimizing carbon capture technology. In this rotation, engineers will have an opportunity to conduct economic analyses the Department of Energy as well as provide reports for customers. Additionally, there will be opportunities to develop and standardize tools to further enhance understanding of heat balances for alternative fuels and improve thermoeconomic understanding.

CCP Systems – Plant Process and Performance

This role is catered towards the performance of existing or new power plants. You will have the chance to complete performance analyses for plants with unique systems. Involvement with the systems design teams will also be part of this role, as performance inputs are required to design them. Lastly, the performance team will not only assist in power maximization but also will assist with heat rate minimization to improve a variety of plant performance parameters, such as efficiency and output.

Customer Application Engineer

In the role of a Customer Application Engineer you focus on power plant integration and for multiple Customers it involved plant optimization with Carbon Capture technology. In this rotation, I analyzed the economic evaluation for LCOE (Localized Cost of Energy) for Department of Energy (DOE) FEED Studies at Plant Barry in order to support the DOE report for Calpine Energy. We worked on the standardization of tools for CCS (Carbon Capture and Sequestration) Team, to implement the LEAN methodologies to our process. I looked at Heat Balance reports to relate Gas Turbine heat balance sheets to relevant carbon capture parameters and managed contractors through economic evaluations for state-of-the-art solvent blending for advanced carbon capture.

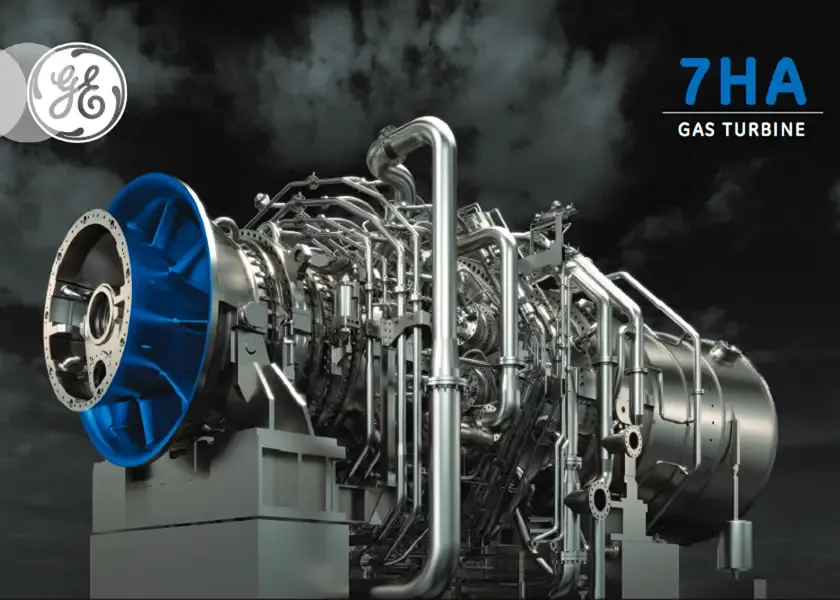

Combustion Design Engineer

In this design engineering role, I was focused on designing, analyzing, and optimizing current GE combustion systems, as well as supporting combustion testing for alternate fuels. Some of my responsibilities included supporting the testing team in the combustion lab for aerothermal or mechanical design changes, conducting the combustion data analysis to improve system performance and understanding, and assisting with site support in order to support the findings of root-cause-analysis. Optimization of combustion systems is a key factor for overall system efficiency and promotes Future of Energy goals by the reduction of fossil fuel consumption or reductions in emissions.